Every year we hear from hundreds of growers from across the globe about their need for product traceability. However, the request also comes with a caveat: harvest traceability needs to be simple to use and it shouldn’t slow things down during the busiest time of year.

What is meant by traceability?

For orchards or farms, traceability refers to the ability to track and trace the origin, movement, and location of fruit from an orchard to the point of sale. It usually includes information such as the fruit type, variety, the orchard location, the date of harvest, and any other relevant information, such as treatments applied to the fruit.

What are the benefits of traceability?

Traceability is important for farms or orchards because it allows growers to track the history of a specific crop, from the time it was planted to when it was harvested and sold. This information can be used to identify any potential issues with the crop, such as pests or diseases, and to make informed decisions, such as how to improve the yields of a particular block or increase efficiency.

Traceability also helps with quality control, food safety, supply chain management, compliance, and transparency.

Bin Tagging

Bin tagging has come a long way since the days of handwritten bin tickets that only contain a limited amount of information.

Today, AgTech companies like Hectre provide farms and orchards with printable, waterproof bin tickets with QR codes or barcodes, capable of storing an array of information connected to a digital record ensuring maximum traceability and ease of access to important data.

From supervisors to tractor drivers to warehouse managers, accessing traceability data is as simple as scanning the bin ticket with an iPad, cellphone, QR/barcode scanner, or by opening up the Hectre app to view the digital record.

Hectre bin tags show all the necessary information with a QR code that can be scanned to bring up the digital record.

How does bin-tagging traceability work with Hectre?

At Hectre, we’re all about creating smart tech that is also easy to use.

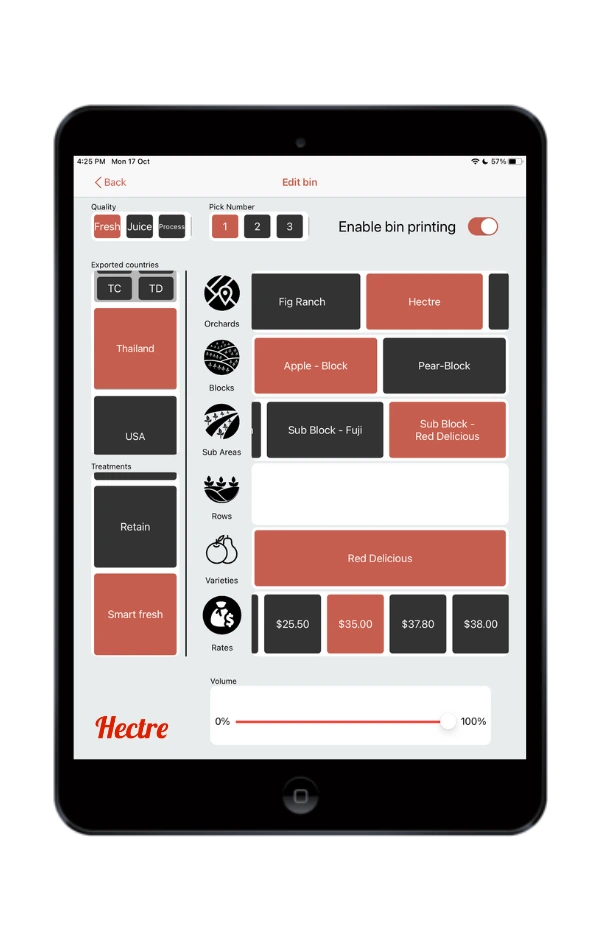

With Hectre’s harvest module, you have control to decide what you would like included on any individual bin tag. It might be:

- Fruit Type

- Variety

- Farm/Orchard

- Block/Lot

- Rate

- Picking Date

- Quality Grade

- Quantity

- Destination

- Treatments (fertilizers, chemical sprays, etc)

You can also decide what information is displayed on the printed bin tag and what just goes into the digital record.

What size or type of business will benefit from Hectre traceability?

Hectre works with businesses of all sizes from around the world. Whether you are a grower with 100 acres or a vertical company with multiple growers on several thousand acres, Hectre works closely with you to find unique solutions for your business.

Read how other growers are using the Hectre Orchard Management App in these case studies.

How are bin tags created?

With Hectre bin tags, you simply select the information you would like the bin tag to contain in the Hectre app. The bin tag is then printed in the field on waterproof paper, ready to be stapled to the bin.

Information provided to Hectre when you become a customer, such as block or lot locations, is used to make this process quick and easy.

Bin tags can be printed within three seconds on waterproof paper in the field on mobile printers attached to your belt.

How does bin tracking work?

Hectre’s unique geo-tagging approach to bin tickets means you are able to trace fruit back to within meters or yards of where it was picked. Geo-tagging also allows for a real-time view of the pick as it moves through the orchard, which means a better-planned and more efficient harvest.

Whether it’s a bin, bucket, or tray, the tag makes it easy to track and capture all the information you need.

Can Hectre bin tags work with different systems?

Yes, Hectre works with its customers to create QR codes or barcodes to match your warehouse packing requirements. Whatever information your packhouse requires, it can easily be added to a Hectre bin tag or stored in the QR code for the packhouse to easily scan and access if they need to.

Contact us to find out more.

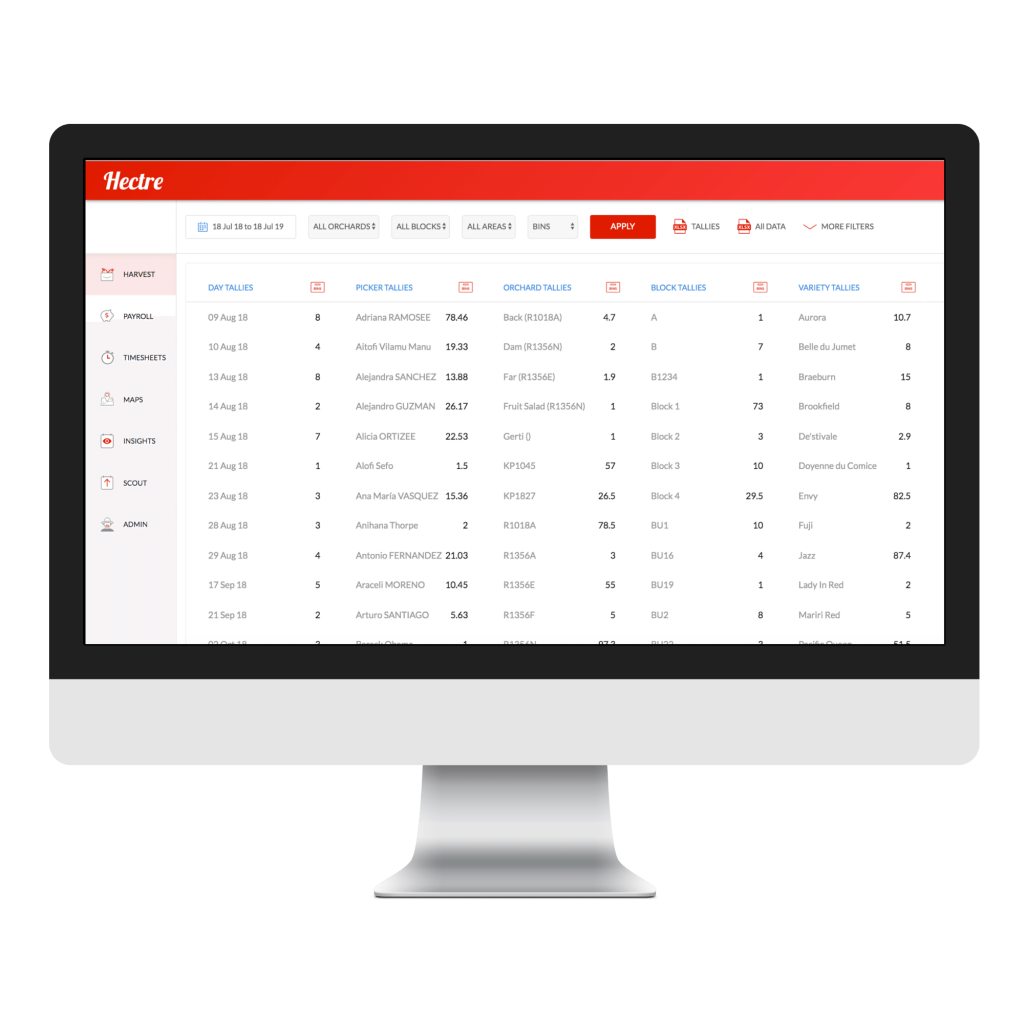

How is traceability information accessed?

Information collected with Hectre is stored in the Hectre app, easily accessible by you, and shareable from anywhere on a mobile device or desktop computer. Best of all, it’s live information, which gives you the ability to track what’s going on in the orchard in real-time.

View and generate reports

The Hectre app also provides you with easy-to-generate and access reports to help with planning and decision-making.

For example, you can see how many bins were picked from a row, how long the pick took, and how many staff were required. The reports can also be used to demonstrate compliance with regulations and for auditing.

What do Hectre customers say?

Chris McInally from New Zealand’s Moana Orchards notes the following regarding quality control.

“With the traceability that Hectre gives us, less is getting past us. In fact, because we can get all the data so quickly and easily, we probably use Hectre and the data it provides more often than we think. It’s so simple to just pull out your phone, see what’s going on, and use those insights to help with your decision-making.”

Here’s what Australia’s Fankhauser Orchards had to say about Hectre’s harvest traceability and its benefits.

“Being able to push a button on the Hectre App while we’re out in the orchard and have bin tickets printed straight from a portable printer, complete with all of the traceability data we need, makes a huge difference to our operation. No more handwriting bin tickets!

“We can include all of the detail that is required for QA, as well as being able to separate out and review individual pickers, which is always impressive in an audit. Knowing we’ve got this covered with just a couple of clicks equals great peace of mind.”

Got some questions? Want to learn more? Contact our friendly team, or drop us a note here.