The extremely fast pace we work at means finding time for traditional manual size sampling was very challenging. Before having Hectre’s Spectre technology, we would do a receiving sample of 25 apples per truckload. We would look at that small sample of data and set up the packing line accordingly. If the fruit profile ended up being something completely different, we would be left with the wrong setup and a less efficient run.

Sage Fruit

Washington, USA

Sage Fruit is dedicated to providing top-tier customer service and fruit of exceptional quality, always looking to go the extra mile for its growers, packhouses, and customers. They employ numerous horticultural specialists and quality control personnel to ensure they deliver high-quality, fresh produce, year-round, to their customers throughout the US, Canada, Mexico, South America, Europe, and Asia.

Sage Fruit is always looking for new technologies to help us improve our processes and to enhance what we do. When we were approached about Spectre, we were immediately excited about the possibilities. However, it was in its very early stages, so we didn’t really know if it would come to fruition fully the way we hoped it would.

Since those early days, the Hectre team has built upon what they started with, to deliver the product that we envisioned from the start. It’s been an enjoyable process, working closely with the Hectre team, providing feedback, and fine-tuning Spectre for our specific needs.

When looking at new technologies, we are looking for a partner to work with us to create something that works well and solves a problem. Some companies with new technology are extremely proud of what they have done and do not want to pivot from that.

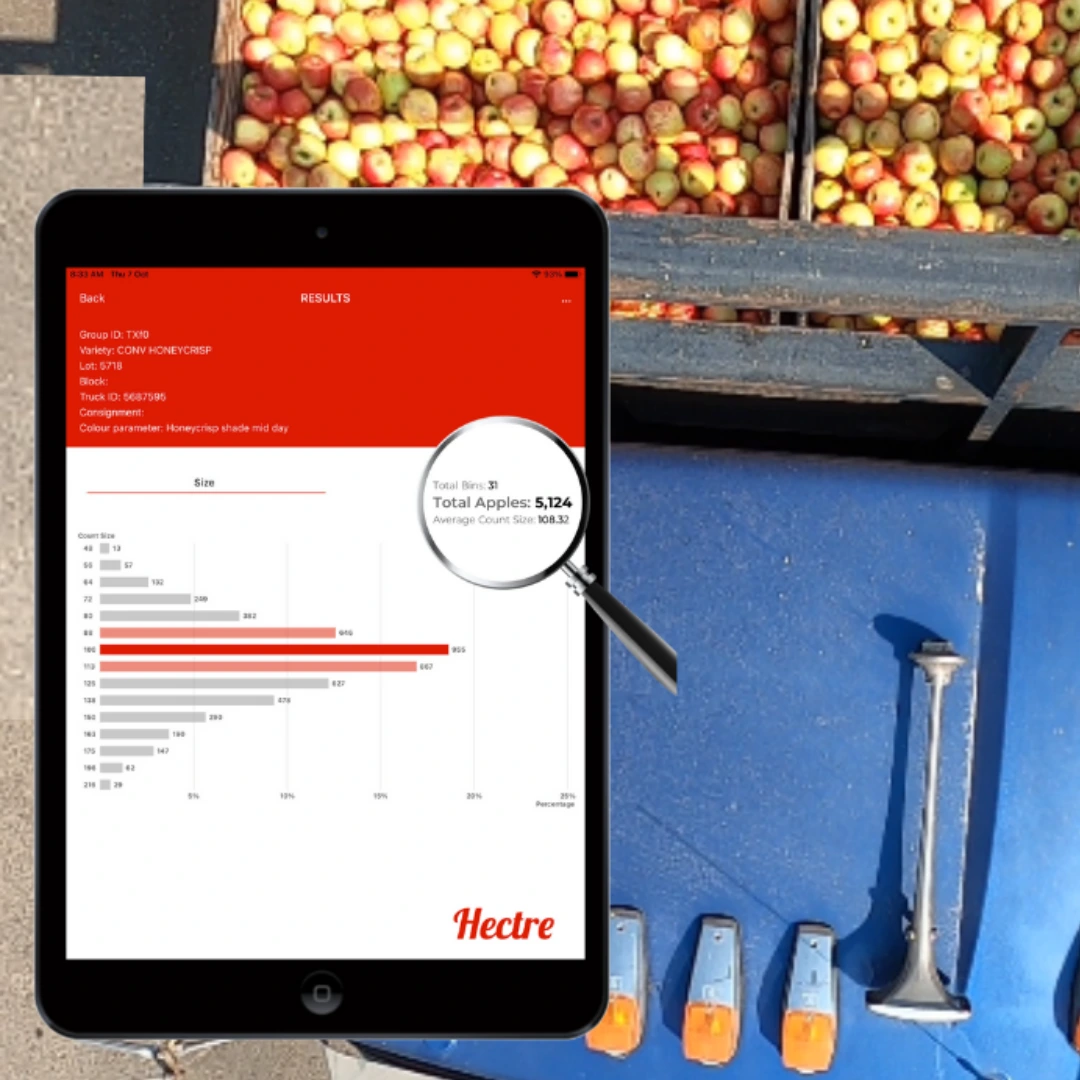

Now that we have Spectre, we have gone from sampling 25 apples per truckload to sampling 6000 apples or more. Our goal this past season was to scan at least 80% of the trucks that come through receiving. Thanks to our focus and our great team, we exceeded that goal, so Spectre’s impact has been huge for us.

Spectre helps us plan and reduce detrimental effects on the packing line, which is extremely beneficial to our warehouses. It allows us to go, okay, I'm going to have a 100-bin run of this size, and then I'm going to reduce the size or put the order from largest to smallest or from highest grade to lowest grade. You also have the ability to control the schedule based on your marketing orders.

Warehouse downtime reduces when drastic changes in fruit size don't occur within a production run. Within an 8-hour run, you might have as many as seven different growers, and if you don't have an accurate understanding of the size, you can find yourself jumping from largest to smallest and back to largest, etc.

Every change on the packing line requires a movement of materials and labor to make the changes, which means we are not running at full speed. So having accurate size profile information ensures we don’t end up with a reduction in throughput.

In the first year, some technological challenges meant we had to work hard to ensure Spectre was being used. However, this year, things went much smoother. We’re in a really good spot now, with fantastic teams in place at all of our warehouses, and from what I’ve heard, they really enjoy using Spectre now.

One method we use to get our warehouse teams on board with using Spectre is appealing to their competitive side. For example, every day, we email the warehouses with the percentage of captures they have successfully added. And at the backend, we have conversations like, "Hey, I noticed your neighboring warehouse beat you by a couple of percentage points! How do we get that number up today?"

It's not easy when you are balancing a lot of things and have trucks lined up down the road, but our warehouse staff have responded extremely well. They monitor those KPIs just like we do and have become rerally good at realizing when they are falling behind and need to pick up the pace. A little friendly competition goes a long way!

On the sales and marketing side, Spectre has made it a lot easier to match the fruit we have, to what the customer demand is, and to optimize our run schedules accordingly.

It has meant we have greater capability to ensure we run the right fruit at the right time to fulfill the demand and ensure we hit the numbers for a customer's order in time.